- Discuss the following techniques of scientific work study.

(i) Time Study

(ii) Motion Study

(iii) Fatigue Study

(iv) Method Study

(v) Simplification and Standardisation of Work

or

Explain any five techniques, which facilitate application of the principles of scientific management.

or

Mention briefly the techniques of Taylor’s scientific management.

Techniques of Taylor’s scientific management :

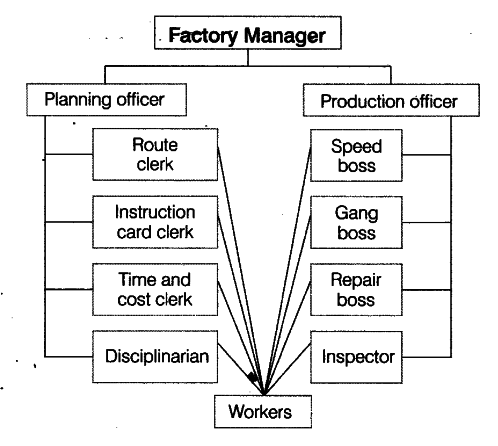

- Functional Foremanship : It is an extension of principle of division of labour, resulting in specialisation. According to Taylor, a single worker or supervisor cannot be expected to be an expert in all aspects. Thus, he advocated the appointment of eight foremen to guide workers, under planning and production departments.

Under the planning incharge, there are four personnel:

(i) Route clerk He is responsible to specify the route of production.

{ii) Instruction card clerk He is responsible to give instructions to the workers.

{iii) Time and cost clerk He is responsible to prepare time and cost sheets.

(iv) Disciplinarian He is responsible to maintain discipline among workers.

Under the production incharge, there are four personnel:

(i) Speed boss He is responsible for timely completion of job.

{ii) Gang-boss He is responsible for keeping machines and tools ready for work.

{iii) Repair boss He is responsible to keep machines and tools in proper working condition.

{iv) Inspector He is responsible to maintain quality of work.

- Standardisation and Simplification of Work: Standardisation is the process of setting standards for every business activity, process, raw materials, rime, machinery and methods, to achieve efficiency.

Standardisation of product implies that the size, design, quality, shape, etc of the product should meet the requirements and tastes of consumers.

The objectives of standardisation are:

{i) To maintain quality standards.

(ii) To set up performance standards of men and machines.

{iii) To provide interchangeability of manufactured parts and products.

{iv) To achieve target production in pre-determined time. Simplification means eliminating superfluous sizes, varieties and dimensions. Its aim is to:

{i) Eliminate unnecessary diversity of products and thereby reduce costs. .

{ii) Help in achieving economy in the use of required machines and tools. - Work Study Techniques

Scientific management requires deep analysis of all the activities performed in an organisation with the aim of producing the maximum possible output with the minimum possible efforts. In his effort to do so, FW Taylor conducted a number of experiments in various areas of production, viz method study, motion study, time study and fatigue study.

(a) Method Study

This technique of scientific management is conducted to find out the ‘one best method or way’ of performing a particular task. The objective of this study is to minimise the cost of production and maximise the quality and satisfaction of the customer.

For this, techniques such as process charts and operations research are used.

(b) Motion Study

Motion study refers to an in-depth study of movements of a worker while doing a task. Taylor recognised three types of movements:

(a) Productive (b) Unproductive © Incidental The objective of motion study is to eliminate unproductive movements in doing a task to achieve efficiency and reduce the time required to do the task. For this, Taylor used stopwatches and various colours and symbols to identify productive and unproductive movements of the employees.

© Time Study

It determines the standard time taken to perform a well-defined job. Time measuring devices were used to conduct this study. This type of study is helpful in deciding the time required to perform a job. It also helps in determining a fair day’s work for the workman and determining incentive schemes and labour costs.

(d) Fatigue Study

Fatigue study seeks to find out the amount and’ frequency of rest intervals to be given to workers in completing a task. This would help the worker to regain his stamina and work with the same efficiency again. It also aims to reduce various causes of fatigue such as long working hours, doing unsuitable work, bad working conditions, etc. The objective of this study is to find out how long a person can perform the standard task without any adverse effects on his health and productivity. - Differential Piece Wage System

Taylor strongly advocated piece wage system. He wanted to differentiate between efficient and inefficient workers. Under this system of wage payment, wages are paid on the basis of work done.

According to him, higher rates were given to the workers who are producing standard products or more and lower rates were given to those who are producing less. - Mental Revolution

It involves change in the attitude of workers and management. Both should realise the importance of the other and should cooperate with each other. Both should aim to increase the size of surplus. Managers should share their gains with workers, while workers should contribute to increase profits. This attitude will bring prosperity to both, the company as well as the workers.